BONDED ABRASIVES

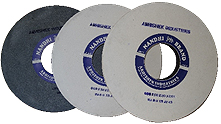

Resinoid Grinding Wheels & Vitrified Grinding Wheels

These are divided into Vitrified, Resinoid Thin Wheels and are manufactured by mixing grains with bonding material, moulding them to shape and then subjecting the output to firing or baking in high temperature and finishing the same to desired dimensions. The composition of the product depends on the type of grains and type of bonding materials used. Sizes will vary between 10 mm to 1200 mm with thickness ranging from 1 mm to 305 mm. Bonded abrasives are mostly in the form of wheels but also in other shapes such as segments, sticks etc. Bonded abrasives for internal purposes classified as Standard Products i.e. those products which are made to standard dimensions, grit sizes, shapes and grain / bond composition.

Non Standard Products are those products which are made to exact requirements of customers. Bonded Abrasives are used in diverse applications like floor polishing, fabrication, polishing, off-hand tool grinding and precision grinding of diverse products like crank shaft, cam shaft across a wide spectrum of industries ranging from automobile, construction, fabrication, steel, bearing etc,,

Cylindrical Grinding wheels

Nandhi’s Ranges of vitrified cylindrical grinding wheels are fast stock removal, fine finishing and reduced dressing frequency.

Application:

Auto OEM, Auto Ancillaries, Bearing & general Engineering, Precision Components

| Cylindrical Grinding wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 250 | 25 | 76.2 |

| 300 | 25 – 40 | 76.2,127 |

| 350 | 25 –50 | 127, 152.4 |

| 400 -500 | 25 – 75 | 152.4, 203.2 |

| 600 | 13 – 75 | 203.2, 254, 304.8 |

| 700 -750 | 25 – 100 | 254, 304.8 |

Centre Less Grinding wheels

Nandhi’s range of vitrified & Resinoid Grinding wheels is designed for versatility in grinding materials of different hardness.

| Centreless Grinding Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 300 | 80, 100,150 | 50.8, 76.2 |

| 350 | 100, 150 | 127, 152.4 |

| 400 | 100,120,150,200 | 203.2 |

| 450 | 100,150,200 | 203.2, 254 |

| 500 | 150, 200, 250, 300 | 254, 304.8 |

| 600 | 150, 200, 254, 305 | 304.8 |

Roll Grinding Wheels

Nandhi’s Roll grinding wheels are made with premium abrasive grain and premium bond.

Industrial Use:

Paper and steel rolling mills,general engineering, precision grinding work

| Roll Grinding Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 550 | 40 | 203.2 |

| 600 | 40, 50 | 203.2 |

| 660 | 40, 50 | 203.2, 304.8 |

| 700 | 50, 60 | 304.8 |

| 760 | 50, 60 | 304.8 |

Crankshaft Wheels

Nandhi’s Vitrified Crankshaft wheels are micron surface finishes. Wheels can be made to operate up to 60 mps.

Application:

These type of wheels are ideal to grind shaft surfaces of different hardness with different grades.

| Crankshaft Grinding wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 550 | 17 – 22 | 203.2 |

| 600 | 17 – 22 | 203.2 |

| 700 | 17 – 25 | 254, 304.8 |

| 760 | 22 – 38 | 304.8 |

| 800 | 32 – 40 | 304.8 |

| 915 | 40 – 45 | 304.8 |

| 1065 | 40 – 45 | 304.8 |

Surface Grinding wheels

Nandhi’s range of surface grinding wheels having various type of grades and sizes. We having special bonding and processing system for different grades.

Industrial uses:

To use flatten the surfaces of bar & other engineering works, sharpen knives and blades, large mould surfaces.

| Surface Grinding Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 150 | 25 – 50 | 38 |

| 200 | 25 – 50 | 38, 50.8, 76.2 |

| 250 | 25 – 80 | 76.2, 127 |

Thread Grinding wheels

Nandhi’s range of thread and gear grinding wheels are high dimentional accuracy, wheels are having long life, it will reduce dressing frequency.

Industrial use:

External Thread, taps 7 rolls, internal thread gauges, and dies

| Thread & Gear grinding wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 220 | 84 | 76.2 |

| 300 | 125 | 76.2 |

| 350 | 84, 104 | 160 |

| 400 | 84, 104 | 160 |

Off Hand Grinding Wheels

Nandhi’s vitrified Offhand grinding wheels are made with brown aluminium Oxide and Black Silicon Carbide with special bonding to achieve large castings & Forgings.

Industrial use:

Foundry & forging, Metal fabrication, General Engineering, Hand tool Application and etc…

| Off Hand Grinding Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 100 – 125 | 13 | 25.4 |

| 150- 180 | 13 – 25 | 25.4 |

| 200 – 250 | 25 | 31.75, 38.1 |

| 300 -350 | 50 | 38.1, 50.8 |

| 400 – 450 | 50 | 50.8 |

| 500 | 75 | 152.4 |

Tool Room Grinding Wheels

Nandhi’s range of tool room grinding wheels are made for high material removal rate, reduced cycle time and lower grinding cost

Industrial Use:

Tools & dies, Cutting tool and general engineering, Metal Fabrications, Construction Industries

| Tool Room Grinding Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 75 – 100 | 13 – 25 | 12.7, 20.0 |

| 150 | 6, 13, 20 | 16, 31.75 |

| 180 | 13, 20 | 31.75 |

| 200 | 6 – 20 | 31.75 |

| 250 | 25 | 76.2 |

| 300-350 | 25, 38 | 76.2 – 127 |

Rice polishing Wheels

Nandhi’s wide range of rice polishing wheels are made with silcon carbide grains of both black and green and also with special bond.

Industrial Use:

Rice Polishing Industries, Food industries. All standard sizes we are made, 250 , 260, 300, 310, 400,etc,,.

| Rice polishing Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 250 | 60 | 160, 170 |

| 260 | 60 | 160, 170 |

| 300 | 60 | 170 |

| 310 | 70 | 210 |

Saw Gumming Wheels

Nandhi’s range of vitrified saw gumming wheels are used in sharpening of the teeth of different types of saw blades. Made with suitable bond combination to give high cut, long life

Industrial use:

Saw manufacturing, Construction and wood work, General Timber.

| Saw gmming Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 100 – 125 | 3 – 6 | 31.75 |

| 150 – 180 | 4 – 6 | 31.75 |

| 200 | 4 – 8 | 31.75 |

| 250 | 10 – 13 | 31.75 |

Mounted Points

Mounted Points are capable of reaching places inaccessible to larger types of Grinding Wheels. It can be used safely on hi-speed portable grinding machines

Nandhi’s Mounted Points are available in various abrasives to suit every need of the end user.

All standard Types of mounted points we are made with suitable bond and grains combinations, etc,,,

*Type A | *Type B | *Type W

Industrial Use:

Deburring, Tool Sharpening , Removing Metal marks and parting lines. Finishing cavities, Smoothing intricate profiles of castings, forgings. Die Grinding, Grinding of Steel Rolling Rolls

Internal Grinding Wheels

Internal grinding wheels are used in the production of precision components demanding a highly accurate geometry and surface.

Industrial Use:

Bearing, Small cylinder, Compressor parts, Injection nozzle parts, Gear parts, Hydraulic cylinders, Tappets

Grinding Segment

Grinding wheel segments are generally used to grind flat stock or flat surfaces within a workpiece for anything from heavy stock removal to precision grinding. Available in a variety of shapes, sizes and grain types to meet your job requirement.

Straight & Tapper Cup Wheels

Nandhi’s range of Cup Shape Grinding wheels also comes with multiple types of bond, Cup wheels also known as Taper Cup Wheel are used for re-sharpening Blades. We offer straight and Taper Cup wheels for various grinding application.

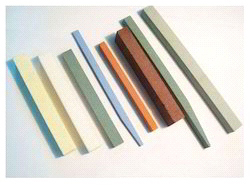

Dressing Sticks

Dressing Sticks and Hones Specialities are abrasive stones, sticks, blocks or cylinders of various sizes and cross sections. Used for Sharpening and reconditioning chisels,plane irons gauges,knives, scythes, axes, shears and for polishing marble, mosaic, granite etc. These are made specifically to suit particular needs and the use of the right product will ensure both ease and speed in carrying out the sharpening or polishing jobs.

Product Description and Applications:

Combination stone : Designed to clean magnetic chucks

Dressing wheels : Break control devices used for dressing / opening diamond wheels

Dressing sticks : Dressing and opening vitrified bonded wheels.

Resin Bonded Snagging Wheels

Nandhi’s Snagging Wheels are manufactured for a wide use of heavy stock removal in foundries, welding shops, metal fabricators, steel mills, shipyards etc.

Nandhi’s offer a complete line of engineered snagging wheels of high performance and many types such as Straight Wheels, Flaring Cups, Cones and Mounted Points.

Snagging wheels can be used on portable hand grinder, Pedestal grinder and swing frame grinder.

| Resin Bonded Snagging Grinding Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 50 – 100 | 13 – 25 | 10, 15.88 |

| 150 | 20 – 25 | 15.88 |

| 300 -350 | 40 – 50 | 31.75, 38.1, 50.8 |

| 400 -450 | 40, 50, 63 | 50.8, 127, 152.4 |

| 500 | 50 -75 | 203.2, 254,304.8 |

| 600 | 75 | 203.2, 254, 304.8 |

F-Type ( Nut inserted Wheels)

Nandhi’s range of nut or bolt inserted discs and plate mounted discs. are available in various sizes. Ranging from 250 mm to 660 mm in diameter with usable abrasive from 25 mm to 100 mm in thickness.

Industrial Use:

F-Type Wheel used for Bearing face grinding. Piston ring face grinding, Coil spring end grinding, Vertical spindle surface grinding. Valve plate grinding, Auto and auto ancillaries.

Cut- off wheels

| Cut off Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 100 | 4 | 10 |

| 125 | 4, 6 | 10, 15.88 |

| 180 | 3, 3.2, 4 | 22.23 |

| 230 | 2.5, 3.0, 4, 5 | 22.23 |

| 300 | 1.5, 2.5, 4, 7, 12.5 | 22.23, 25.4 |

| 350 | 3.2, 4 | 25.4 |

| 400 | 3.0, 4.0, 4.5, 8 | 25.4,31.75, 40, 76.2 |

| 500 | 3.5, 4.5, 5 | 31.75, 40.0, 76.2 |

Grinding & Cut- Off Wheels

Nandhi’s grinding and cutting discs are produced in the state of the art ISO 9001:2015 certified manufacturing facility, with stringent process controls and final product quality checks. By this, not only the best grinding performances are achieved. The uniqueness of the product design allows for the most optimum grinding performance

Good cutting action with tool life, consistently throughout the product life. The core strength of Nandhi brand has been the ability to customize products for specific application needs

Application:

Auto OEM, Auto Ancillaries, Bearing & general Engineering, Precision Components

| DC Grinding Wheel | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 100 | 4, 6 | 15.88 |

| 125 | 5, 7 | 22.23 |

| 180 | 6, 7 | 22.23 |

| 230 | 5, 7, 8 | 22.23 |

Ultra Thin 1 mm Cutting Wheels

| Ultra Thin 1 mm Cuting Wheels | ||

| Dia (mm) | Thick (mm) | Bore (mm) |

| 100 | 1 | 15.88 |

| 105 | 1 | 15.88 |

| 115 | 1 | 15.88, |

| 125 | 1 | 22.23 |

| 150 | 1 | 25.4, 31.75 |

| 180 | 1 | 31.75 |

| 200 | 1 | 31.75 |